Why Investment Casting is a Cost-Effective Manufacturing Solution

- Saffroshine

- Jul 10, 2025

- 4 min read

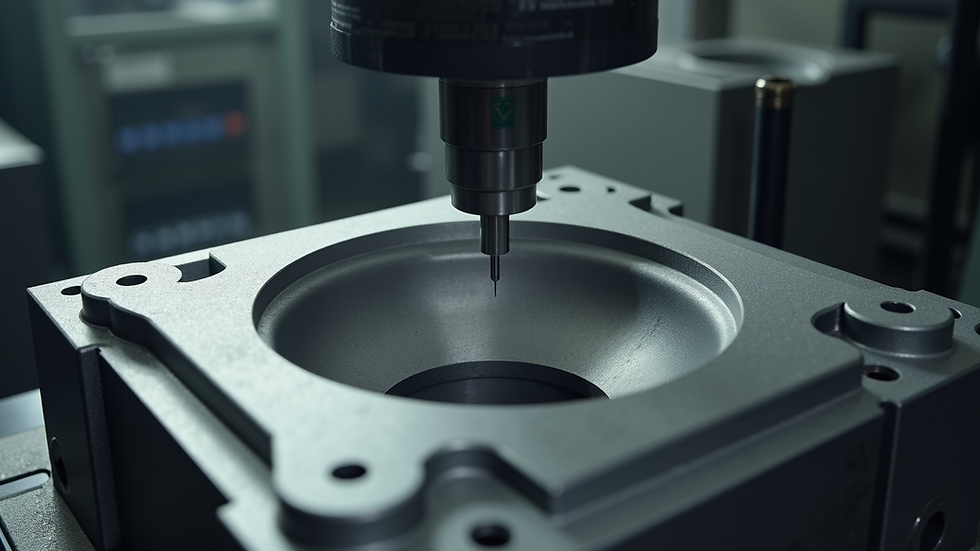

Investment casting, also known as lost-wax casting, is a manufacturing process that offers precision, complexity, and high-quality finishes. Many industries, from aerospace to medical devices, rely on this sophisticated method. But one question often arises: Is it a cost-effective solution? In this article, we’ll explore why investment casting stands out as a budget-friendly manufacturing option.

Benefits of Precision Casting

Precision casting minimizes waste, which contributes significantly to cost reduction. Unlike traditional machining, which removes material from larger blocks, investment casting involves creating a mold that matches the exact specifications of the desired part. This means that the amount of material used is directly proportional to the part size, generating minimal scrap. This efficiency leads to lower material costs and reduced waste disposal expenses.

Additionally, intricate designs can be achieved with investment casting, which decreases the need for additional processes, such as machining or finishing. With reduced need for these secondary operations, the production lead time decreases as well. Companies can not only save on labor costs but also speed up the time it takes to bring products to market.

Understanding Investment Casting

Investment casting is a process that creates complex shapes using a mold. The technique begins with a wax model of the part, which is coated with a ceramic material. Once hardened, the wax is melted away, leaving a precise mold ready for metal to be poured in. This process allows for exceptional detail and high tolerances in the final product.

The versatility of the investment casting process means it can handle a variety of metals, including aluminum, steel, and even exotic alloys. This flexibility is beneficial to numerous industries, particularly those that require specific performance characteristics at lower weights, such as aerospace.

What are the Advantages of the Casting Process?

There are numerous benefits to using investment casting as a manufacturing solution. Here are some of the key advantages:

High Precision and Complexity: Investment casting can produce intricate geometries that would be difficult, if not impossible, with other manufacturing methods. This is especially useful in areas like aerospace, where parts must meet tight tolerances to ensure performance and safety.

Material Variety: As mentioned earlier, the process can accommodate different types of metals and alloys. This allows designers to select materials that best fit their application's demands, whether that's heat resistance, corrosion resistance, or tensile strength.

Reduced Assembly Costs: Because investment casting can create parts in one piece, companies can significantly reduce the number of components they need to assemble. This not only cuts down on labor but also decreases the risk of failure at assembly points.

Less Waste: As previously noted, the investment casting process minimizes material waste, translating into lower raw material costs and reduced environmental impact.

Scalability: Investment casting is highly scalable, making it an ideal solution for both low-volume custom orders and high-volume production runs.

Overall, these factors contribute to making investment casting a highly attractive option for manufacturers looking to balance cost and quality.

Competitive Edge with Investment Casting

Industries that embrace investment casting gain a competitive edge through enhanced quality and capabilities. For example, in the aerospace sector, precise and lightweight components can improve fuel efficiency and performance. Similarly, medical device manufacturers benefit from precision and reliability, essential factors for patient safety.

According to a study by the American Foundry Society, investment casting can reduce production costs by up to 40% when compared to other methods, especially when considering the comprehensive benefits of reduced waste and shorter lead times. This economic advantage can be a powerful differentiator in an increasingly competitive marketplace.

Recommendations for Implementing Investment Casting

To fully leverage the benefits of investment casting, businesses must consider a few key recommendations:

Choose the Right Partner: Not all investment casting manufacturers are created equal. Research potential partners carefully, looking for those with a strong reputation and proven track record in your industry.

Invest in Design for Manufacturing (DFM): Collaborate with your casting partner early in the design stage to ensure that designs are optimized for the casting process. This involves considering factors such as the thickness of walls, draft angles, and overall geometry.

Conduct Reliability Testing: Once samples are cast, conduct rigorous testing to assess performance and ensure that parts meet all industry standards. This can save time and costs in the long run.

Monitor Market Trends: Stay updated on advancements in materials and casting techniques. As new technologies emerge, opportunities for cost savings and efficiencies may present themselves.

Final Thoughts on Investment Casting

Investment casting emerges as a powerful option for manufacturers who seek to combine quality with efficiency. The many advantages of investment casting make it not only a viable solution for many industries but also a cost-effective strategy in the long run. The ability to produce high-precision parts without excessive waste, alongside the versatility of materials used, solidifies investment casting's position in the competitive landscape.

As more industries recognize these benefits, investment casting may well become the go-to process for manufacturing high-quality, cost-effective components. Leveraging this process can lead not only to lower production costs but also to a stronger position in a fast-paced market landscape.

Comments